The Córdoba Operations Center, located on the outskirts of the provincial capital, continues to grow. The local team handles a constant flow of shipments of resins, gelcoats, fiberglass, and auxiliary materials, ensuring close and rapid service.

Construction is already underway on the Training Center, a space dedicated to technical training and professional development, designed to support clients and their employees. There, workshops and training sessions will be held focusing on the use of composite materials, production processes, and best application practices.

In the next phase, and always aligned with our goal of providing integrated solutions to our clients, we plan to add a Tool and Die Center, which will offer die repair services and adaptation to the VPI process.

With these initiatives, we aim to consolidate a value proposition that combines close customer relationships, technical support, and operational efficiency, helping our clients develop more robust and competitive processes.

Swancor resins were recognized as finalists in the Vinyl Ester category of the 2025 ALMACO Brazil Top of Mind Awards, an achievement that highlights their strong presence and brand recall within the regional market.

This recognition strengthens Plaquimet’s presence in Brazil, reflecting the excellent reception achieved thanks to the combination of our specialist technicians’ work and product quality, positioning Swancor as one of the most popular choices in the region.

The Top of Mind Awards have become the leading indicator of brand recall in the sector, highlighting those who generate a real impact on the market and set trends within the industry.

Being among the finalists demonstrates a sustained commitment to innovation, performance, and reliability—attributes highly valued by the professionals and companies that participated in the national survey organized by ALMACO.

For Plaquimet, accompanying Swancor in this recognition is a source of pride and a sign that we are moving in the right direction: strengthening the regional offering, promoting cutting-edge technologies and contributing to the development of a more competitive and sustainable sector.

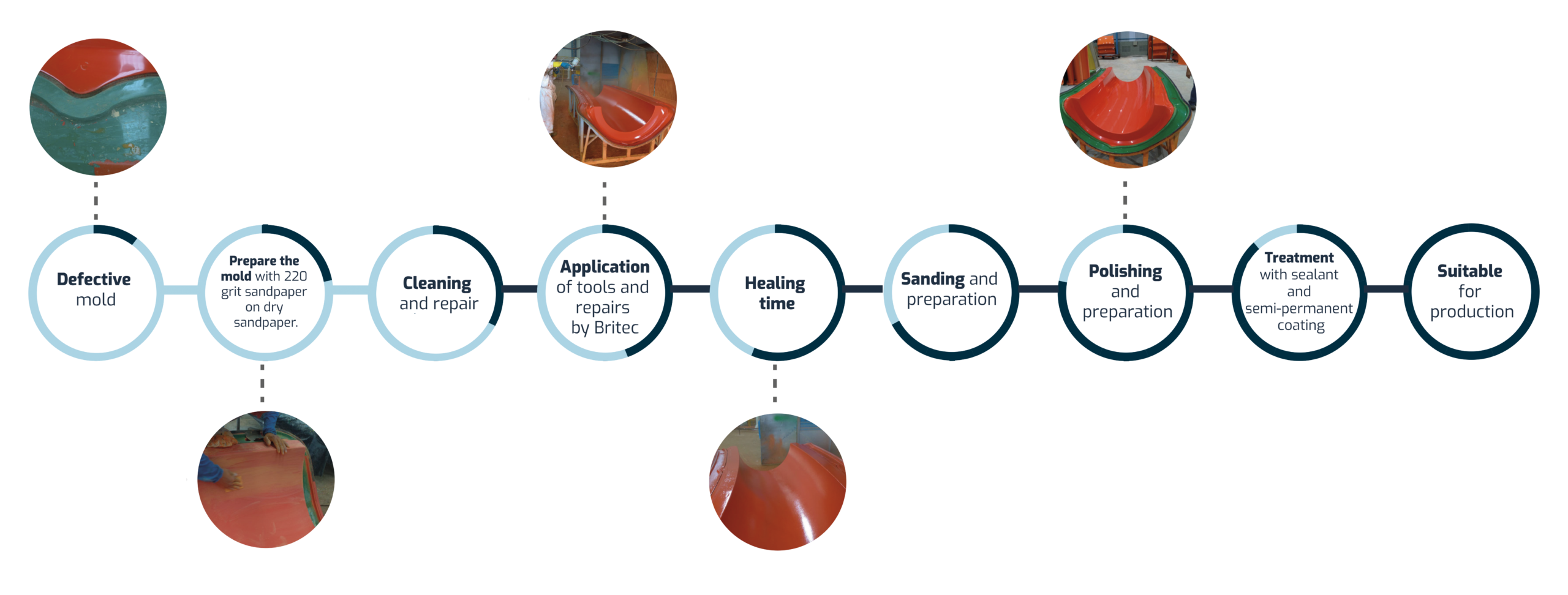

With use, molds wear down, affecting the quality of the parts. To solve this, Plaquimet combines Britec Tooling and Britec Repair.

Our technical team can guide you step-by-step to ensure a flawless result.

The Latin American Association of Composite Materials (ALMACO), in conjunction with the Institute of Technological Research (IPT), announced the launch of a new postgraduate program in composite materials and polymers, which will begin in March 2026 and will be offered online.

The program is designed to provide participants with comprehensive training that will enable them to:

Those interested can request more information and register through the link https://bit.ly/MateriaisCompositosPolimerosIPT by writing to cursos@ipt.br or by calling +55 11 3767‑4226.